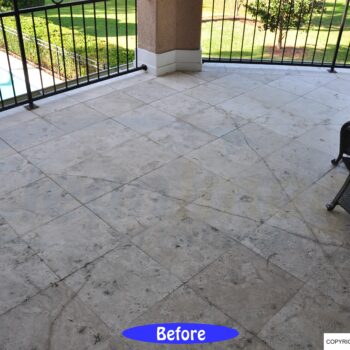

Grinding a Travertine floor flat is warranted if you have the following conditions; you stub your toe on tiles sticking up when you walk across your floor, the uneven tiles are so bad it looks like a 12 year old installed the floor, or maybe it is the unslighty shadows created when the sun shines in your home. These problems and more can be solved by grinding your Travertine, or any stone floor flat. Call 407-298-3132 and ask for details and free estimate.

Grinding Travertine

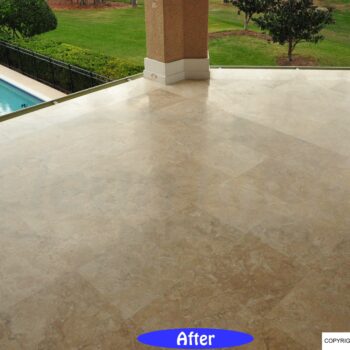

Even though this was a hi-hone finish and not a hi-polish, when the customer walked up to the front door, she thought the floor was wet. I think this was more because the floor was not flat, and resulted in a consistent natural shine rather than individual tiles sticking out of the floor.

The most common reason customer will have their floors ground flat, is because a floor with significant lippage is unsightly. Especially at certain times of the day when the sun shines across the floor and casts shadows that look like soil lines. If you have a floor that is difficult to clean, has deep grout lines, you trip across some tiles, you may want to get an estimate to have your floor ground flat. This is a process that is done once in the life a stone floor.

This Homeowner in Magnolia Plantation was disappointed when she had her travertine installed and it was left with so much lippage, or uneven tile heights. They would sometimes trip over some of the worst lippage. Clean Image was able to grind the entire floor flat and finish to a hi-hone finish. You can see from the close up, that after a grind and fill process, the grout lines are near flush with travertine, this make cleaning much easier, and will help control those dreaded dirty grout lines that are difficult to clean because they are so recessed.

Another advantage of grinding your floor flat is the grout lines are now flush with the stone. So it will make future cleaning much as easier as grout typically is the lowest point on floors and that were all the soils like to accumulate. With flush grout lines your vacuuming and cleaning is much more effective.

After this travertine floor was installed, the owner noticed raised tile edges that cast shadows and was unacceptable. The installer then sanded just the edges to ‘fix’ the problem, which opened holes and created unsightly dull strips in the middle of his floor.

The owner was generally unhappy with the finished product, and wanted a higher polish to the travertine. Clean Image of Orlando went over various options with the owner and decided to use our Italian equipment with diamond abrasives to grind the floor flat. This process is done wet, and is contained so there is absolutely no dust.

After grinding the travertine flat, epoxy resins were used to fill the holes created. Epoxy resins will consolidate the stone, making it more durable, and will take a shine unlike the cementitious fill normally found in travertine.

The travertine floor is then diamond honed, diamond polished, and active polished to create a high gloss that brings out the natural beauty of a travertine floor.

Here are 3 pictures that show the floor before we started, after we ground flat and over filled with modified cementitious filler, and the last picture is the final finish. One important aspect of grinding a travertine flat, is addressing the holes that will be inherently opened up, or more accurately exposed, during the grinding process. What you are looking at in the middle picture is the filler that is over applied to the travertine and allowed to cure, typically overnight. What this allows, is even if the filler shrinks into the hole or grout, it is still filling. Because it is overfilled, when we come in during our next step and diamond hone the entire floor, that filler will be near flush with the travertine. Some companies to save time and diamond pad costs, and will sponge the grout after filling and this will leave you with unsightly and soil grabbing recessed holes and grout lines. Our motto at Clean Image is: we like to treat our customer’s floors as if they were our own.

How to Know When Travertine Needs Ground

This is an example of bad lippage and what travertine looks like after grinding and before the filling process. There are different fillers that can be used including cementitious, epoxy, polyester, acrylic and urethane. There is much skill required to have the fill remain flush with the surrounding travertine instead of recessed.

See more Travertine Restoration Services.